Norconsult

Driving digital transformation through Norway’s dramatic landscape

The New Possible

Share this story

Platform technology helps teams meet the challenge of building infrastructure in rugged terrain

In a world that needs more infrastructure to meet the challenges of the 21st century, demands on the construction industry are growing. Complex builds that must meet tight timelines and rigorous sustainability requirements can require daunting feats of technological innovation. Along the rugged coast of southern Norway, engineering and design consultancy Norconsult took on the challenge of delivering a vital highway upgrade across jagged glaciers and deep fjords. In the process, the company has adopted platform technologies that connect teams in a unified environment—enabling Norconsult to drive digital transformation and deliver engineering marvels.

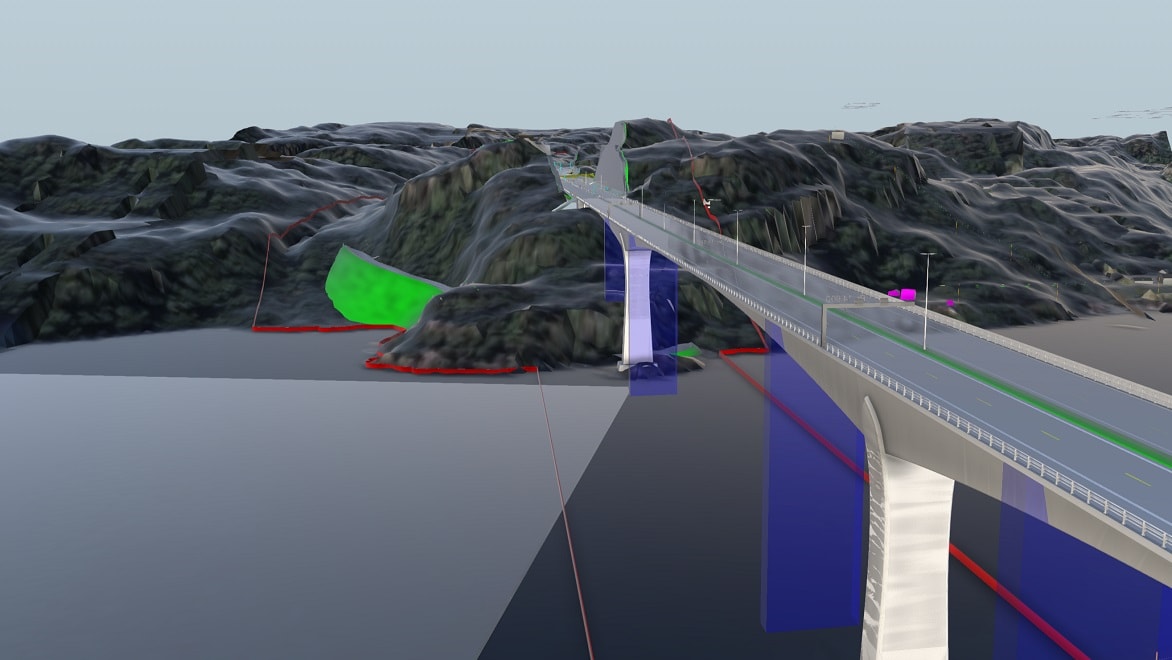

A rendering of Trysfjord Bridge, the world's largest balanced concrete cantilever bridge, part of the E39 highway upgrade project in southern Norway. Image courtesy of Norconsult.

5 tunnels, 47 structures, and the world’s largest cantilever bridge

Roads, tunnels, and bridges are more than just infrastructure projects in Norway—they are strategic investments in the future. The ambitious Coastal Highway project aims to connect the country’s rugged west coast via Route E39, 700 miles of winding road that takes 21 hours and seven ferry rides to traverse. To modernize a 15-mile stretch from Kristiansand to Mandal, Norway’s road authority has invested $490 million on a four-lane roadway that includes five tunnels, 47 structures, and the world’s largest balanced cantilever bridge.

The road authority had strict criteria for the project’s digitalization using advanced building information modeling (BIM) technologies to interconnect the design and the built environment. Upping the stakes further, the client attached ambitious goals to this endeavor: reduce the project’s carbon emissions by 20% and do it all in four years.

“There were a lot of demands from the client that could not be met using existing tools. The only way to fulfill them was strategic cross-industry collaboration between designers, contractors, and software developers.”

—Marius Jablonskis, Technology Manager, Norconsult

Using 3D BIM models and cloud collaboration, Norconsult was able to reduce the use of paper documentation by 95%. Image courtesy of Norconsult.

Digital tools help Norconsult reduce paper use by 95%

Norconsult—one of Norway’s largest technical consultancies with an extensive global project portfolio that includes buildings, bridges, transport, and water projects—accepted the challenge, but needed to create an entirely new way to design and build to meet the ambitious project goals.

That’s where Autodesk Platform Services (APS) came in. Norconsult used APS (formerly Forge) to extend the capabilities of its own collaboration platform. Using Revit, Navisworks, and APS, the project team aggregated more than 800 3D BIM models to build a single source of truth that connected the project’s 2,000 collaborators—not through cumbersome emails and file transfers, but through a simple web browser.

This custom platform technology solution was built to meet the needs of every stakeholder, ensuring the right details reached the right people, from field workers in tunnels to office staff at desks to the client at the Norwegian road authority in Oslo. The result was the centralization of 300,000 documents in a cloud-based common data environment that reduced traditional drawings by 95% and achieved the project’s digitalization goals.

“Autodesk Platform Services provide us with a foundation that enables the granular, real-time data generation and exchange that’s needed to tear down industry silos and truly integrate teams.”

—Frode Tørresdal, Forge Development Lead, Norconsult

Norconsult’s platform solution enables workers in the field as well as office staff to review project details. Image courtesy of Norconsult.

Optimizing processes to meet escalating demands

The Norwegian road authority’s ambitious project goals are representative of larger forces putting pressure on the architecture, engineering, and construction (AEC) industry. Increasingly, governments are requiring digital project delivery with standards that can only be met when data is open and connected. Meanwhile, both public and private sector customers are raising their expectations for sustainable outcomes. Layer on the trends of urbanization, aging infrastructure, and a diminishing workforce, and it becomes apparent that the industry must build differently.

To address these demands, we need to optimize the way we plan, design, build and ultimately operate our infrastructure,” said Theo Agelopoulos, vice president of AEC Design Strategy at Autodesk. “We need better processes, and we need to better leverage insights across multiple data sources. That’s how we gain benefits all the way through the infrastructure lifecycle.”

Optimizing workflows and processes also helps architecture, engineering, and construction firms to overcome long-standing productivity challenges: Today, the industry spends 35% of its time on nonoptimal activities like tracking down project data, fixing mistakes, and resolving conflicts. Norconsult is solving for that exact type of productivity drain by adopting new technology tools to optimize processes.

The Norconsult team used automated modeling and analysis tools to optimize tunnel designs before construction. Image courtesy of Norconsult.

Innovation mindset helps deliver designs 70% faster

With an ambitious four-year timeline for the E39 project, Norconsult tackled the challenge by designing and building in parallel. Using Dynamo capabilities in Revit, the design team automated the modeling and analysis of complex geometry, enabling them to deliver initial designs about 70% faster.

As project development progressed, the inevitable design changes occurred and the common data environment proved its value: When updates were made, almost 70% of the updates would populate automatically, speeding reviews and reducing errors.

These productivity gains gave Norconsult more time to unleash its talent on bigger challenges. Design and construction of the Trysfjord Bridge stretched the bounds of what’s possible, with a 260-meter balanced concrete cantilever span rising high above a scenic fjord. By using generative design in Revit, Norconsult found strategies to reduce the amount of concrete used on the bridge–achieving a 15% decrease in carbon emissions out of the total project sustainability goal of 20%. In addition to that feat, the Trysfjord Bridge opened in December 2021, a full six months ahead of schedule.

Strategic cross-industry collaboration enabled designers, contractors, and software developers to fulfill the seemingly impossible demands of the E39 project. Image courtesy of Norconsult.

Platform technology helps impossible outcomes to become the new possible

Norconsult achieved better outcomes through a custom platform solution that connected teams in a unified environment. “The client demands seemed impossible at first,” said Jablonskis. “But we had support from Autodesk and a flexible platform to create a solution to meet our specific needs, and that made all the difference.”

But the company’s innovation journey is far from over. Its leaders envision using platform technology to harness the power of real-time sensor data and machine learning to create a “self-learning ecosystem” that drives future industry transformation. In this future, the convergence of technology, processes, and people into an integrated system will unlock insights and accelerate new ways of making—and make it possible to achieve impossible outcomes.