In the manufacturing and AEC industries, information is king. With better information, you decrease risk while improving insights. You understand more and guess less. A digital twin harnesses data and provides teams with improved ROI, helping with everything from supply chain management to facilities maintenance.

Autodesk digital twin technology

What is digital twin?

A digital twin is a dynamic, up-to-date representation of a physical object or system. With a complete collection of all data in one place, a digital twin evolves with the flow of real-time input from sensors and more.

A smarter operation in every way

-

Digital twin for manufacturing

-

Digital twin for architecture, engineering, and construction

What are the benefits of digital twin?

-

Optimized performance

Actionable insights, simulations, and a connected view of all online and offline data enable quick and better decisions to optimize performance and efficiency.

-

Full view of all data

Eliminate data silos and unlock value across a project’s lifecycle with all historical data and real-time data in one place.

-

Smarter predictions

With real-time sensor data and predictive recommendations through machine learning and artificial intelligence, maintenance and operations are significantly improved.

-

Faster results

Creating digital twins of complex assets, factories, and processes exponentially improve the value from operations, reduce development work, and increase time to market.

More about digital twin

Explore the digital twin solution for the architecture, engineering, and construction (AEC) and manufacturing industries in more detail and discover how it helps reduce risk, manage complexity, automate processes, and improve team collaboration and project forecasting.

Who benefits most from digital twin?

While digital twin is beneficial to design teams through data management and improved collaboration, it’s the asset’s owners—whether that asset is a building, product, or process—who have the most to gain. And that creates an opportunity. With digital twin, AEC firms can offer added value to clients with improved transparency into the entire design-and-build process, allowing for greater control over everything from project budgets to building operating costs. Manufacturers can streamline processes through automation and improve operational awareness and competitive advantage by connecting the entire workplace, supply chain, and customer base. This completely connected workflow helps manufacturers become more agile, giving them the ability to better respond to industry trends, supply chain disruptions, and market changes.

Why digital twin?

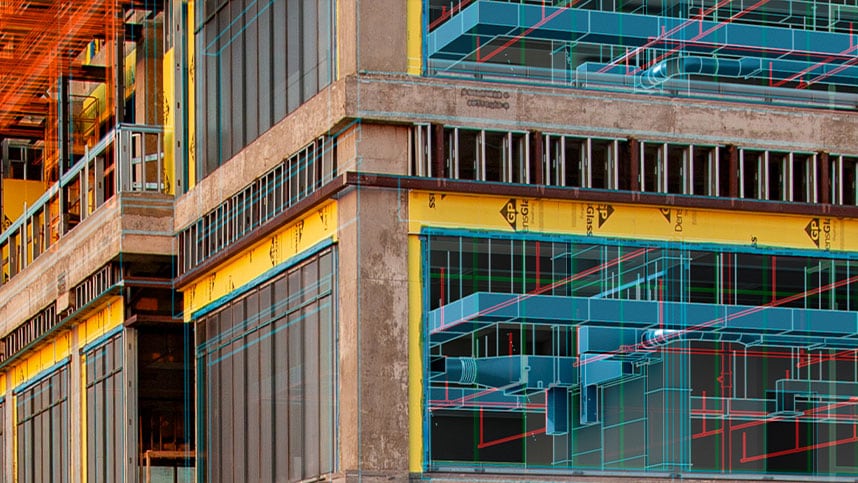

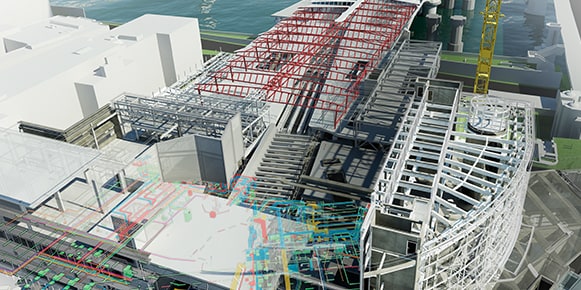

For AEC, digital twin is better with BIM because BIM data is what gives digital twin its value. A digital twin brings together all the data created during the design, engineering, and construction of a structure, creating a comprehensive digital handover of organized, up-to-date, easily accessible data.

For manufacturers, the data collected from a digital twin gives you greater insight into the complete lifecycle of your products and processes, giving you the tools to optimize your workflows, manage your supply chain, and manage product quality, as well as spot any errors before they happen.

Digital Twin Consortium

Autodesk’s participation as a founding member to the Digital Twin Consortium is motivated by our commitment to openness, working with peers to advance industry and improving customer experience in the AEC space.

The Autodesk digital twin solution for AEC and manufacturing industries

Autodesk is a leader in BIM software for the AEC industry and has invested in digital twin concepts for years. Autodesk InfraWorks enables digital twins to help simulate the effect of flooding and traffic flow. And Autodesk Tandem extends the value of all the data created during design and construction, providing a better project handoff, increased insights, and ready-to-go operations.

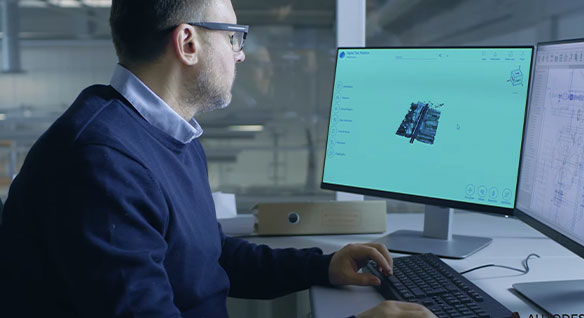

Manufacturers can use Autodesk Forge to power their digital twin. Combining real-time data from multiple sources with a 3D interactive model can help generate greater insights into your project—leading to performance improvements at all phases of the project lifecycle.

Digital twin resources

-

Autodesk Tandem

Explore how you can partner with Autodesk Tandem, the Autodesk digital twin solution for AEC.

-

Digital manufacturing

By offering real-time insights into manufacturing equipment and other assets, digital-twin technology helps to reduce maintenance issues and ensure optimal production output.

Image courtesy of Earl Otsuka

-

What is BIM?

Based on an intelligent model and enabled by a cloud platform, BIM integrates structured, multi-disciplinary data to produce a digital representation of an asset across its lifecycle, from planning and design to construction and operations.

Image courtesy of Network Rail and Jacobs